Juice beverage filling machine is suitable for the filling of all kinds of juice drinks, orange juice, apple juice, strawberry juice, coconut juice, tea beverage and so on. This juice beverage filling equipment can simply adjust some components, and it can also be used for filling pure water and mineral water.

Juice Beverage Filling Machine Introduction:

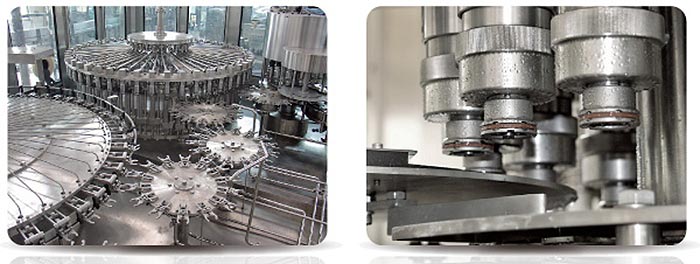

The installation of juice beverage filling machine is a combination of flushing, filling and sealing. Juice beverage filling machine is suitable for the filling of all kinds of juice drinks, orange juice, apple juice, strawberry juice, coconut juice, tea beverage and so on. This juice beverage filling equipment can simply adjust some components, and it can also be used for filling pure water and mineral water. The filling equipment of juice beverage filling machine adopts microgravity negative pressure filling technology, the filling speed is faster, more stable and accurate. The juice filling machine is equipped with a perfect reflux system. It can effectively avoid the two pollution and oxidation of the beverage. It can meet the hot filling technical requirements under 95 centigrade, and is equipped with CIP cleaning system, which can be used for the liquid cylinder and tube. The place of liquid contact is cleaned. Juice beverage filling machine adopts man-machine interface touchscreen control, PLC computer control, inverter control and other advanced technology.

Flushing bottle: The juice beverage bottle is sent to the bottle flushing mechanism by the dial wheel, the bottle clip is opened, and the bottle mouth is clamped. The bottle clip is turned 180 degrees by the guide rail to make the bottle mouth down. The special pump sends pure water to the water distributor of the bottle flushing machine, and realizes the high-pressure washing of the inner wall of the bottle from bottom to top. After washing the orange juice bottle, rotate it 180 times against the clockwise, put the bottle down, and turn the rotary wheel to the filling part.

Filling: filling is made up of a number of filling valves. When the fruit juice bottle is rotated into the filling part, the cam of the upper part of the filling valve controls the lifting and descending of the filling valve. When the filling valve descends, the valve opens and fills. When the filling valve rises, the valve closes.

Juice Beverage Filling Machine Features:

1. Juice beverage filling machine adopts micro-electronic data control, stable performance, easy operation and more humanization;

2. The contact parts with the materials are made of food grade stainless steel, sanitary, easy to clean;

3. The use of efficient Lipper system, with a perfect feeding technology and protective devices;

4. This beverage filling machine is equipped with overload protection device, which can effectively protect the machine equipment and the operator;

5. The control system has automatic height control of the material level, automatic stopping of bottles and other devices;

6. Juice beverage filling equipment structure is complete, the control system is complete, easy to operate, high degree of automation, with suspended filling, different bottle types, bottle thick books can be used;

7. The host adopts variable frequency band control, which can be easily adapted to the production capacity;

8. Cylinder filling power, high productivity, simple structure, easy maintenance;

9. The juice filling machine has an automatic skid device on the screw cap part, and the cap is tightly and tightly closed.